Torque Plate Simulation Honing

When rebuilding an engine, it is essential that a cylinder bore is honed, regardless of whether the engine has been re-bored or not.

| When rebuilding an engine, it is essential that a cylinder bore is honed, regardless of whether the engine has been re-bored or not. Honing a cylinder removes any cylinder markings or minor scratching and creates the perfect bore finish for optimum lubrication for the rings. (Click Here for more on Plateau Honing) |  |

In high performance applications or diesel engines, precision measurements are vital due to the extreme operating conditions. An engine is often honed using a torque plate. This procedure is carried out in order to simulate normal running conditions within an engine.

|

|

|

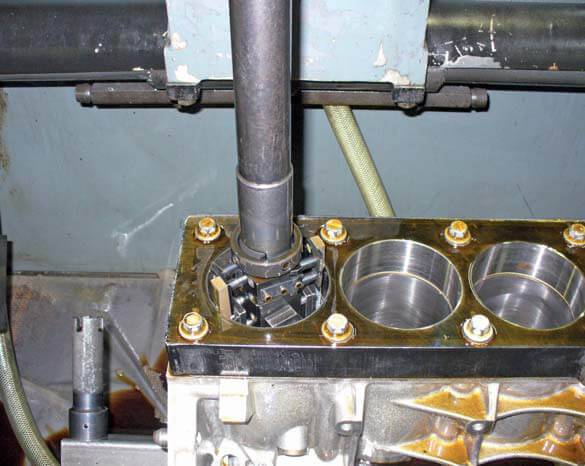

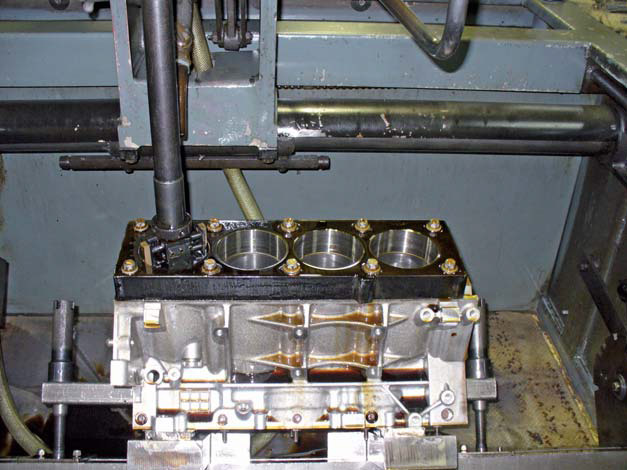

A Chev LS1 honed using a torque simulation plate, used to replicate the distortion created when the cylinder head is installed. Main caps are also installed and tensioned.

When a head is bolted to a block, the load created by the tensioning process causes block distortion. This distortion can alter the geometry of the cylinder. This means that a block without load will have a slightly different shaped cylinder bore to the same block with load. Dimensional variations of .003" to .004" have been recorded. Torque plates are designed to the same specifications as the head of that particular application and are bolted to the block with the same tensions used to clamp the head to the block. By honing a cylinder with the torque plate, you are creating the same conditions in the bore the engine will have under normal operation. Therefore, the resulting hone will be perfectly round when the engine is assembled.

Creating these ideal conditions whilst honing can create many advantages. A cylinder with perfect roundness will create more effective cylinder sealing with the rings. This optimizes lubrication to the cylinder and provides consistent ring wear and rotation. Performance engines operate under extreme pressures, intense temperatures and high rpm. Similarly, diesel engines also operate under powerful forces. These excessive conditions ultimately contribute to greater potential for damage to occur and severe wear. Combining torque plate honing with the correct cylinder finish for your application, will ensure your engine has a long life and reaches its power potential.

| Galloway engines have torque plates to suit many applications. For more information, or to find out how we can meet your engine machining requirements, please contact us. |  |